Airless Bottles

China Cosmetic Airless Bottles Manufacturer

Customized in various sizes and shapes

Prevent bacterial growth

Precisely control dosage

Fully utilize contents

-

5K +Completed Projects5k complete work

-

30 +Our ExpertExpert Airless Bottles

Common Materials

Plastic Airless Bottle

Single layer: AS/PP/PETG

Double layer: out bottle : Acrylic, PETG

inner bottle: PP

Glass Airless Cosmetics Bottle

Double layer: out bottle : Glass

Inner bottle: PP

Aluminium Airless Bottles

Single layer: bottle body AS, cap pump and bottom aluminum

Double layer: out bottle : anodized aluminum

inner bottle : PP

Airless Bottle Supplier Production Flowchart

Customized Cosmetic Airless Bottle Process

1. Design and communication of airless pump bottles details

1.1 Demand discussion

Our managers will communicate specific requirements, including bottle shape, size, capacity, color, surface treatment, printing requirements, etc. For example, one of our brand customers needs a square vacuum bottle with a capacity of 50ml, matte black, and hot stamping brand logo.

1.2 Make a design draft

According to customer requirements, our design team creates a preliminary design draft, which may include 2D sketches or 3D renderings, allowing you to visually evaluate the appearance and structure of the bottle. You can then provide feedback and request modifications.

1.3 Sample confirmation

After the design is completed, we make a physical sample for you to review. The sample can verify the actual effect of the bottle's appearance, size, and function. You can make final adjustments based on the sample until you are satisfied with the design.

1.4 Material selection

Bottle material: Common materials for vacuum bottles are plastics such as PP, PET, AS, and glass. The choice of material depends on factors such as the product characteristics, cost, and brand positioning you provide me. Glass is often used in high-end products due to its good texture and high transparency, while plastic is more widely used due to its light weight and low cost.

1.5 Pump head material

Pump heads are commonly made of PP and metal. Metal pump heads feel more luxurious and have better durability, while plastic pump heads are more cost-effective and lighter.

2. Airless Bottle Manufacturing and Processing

2.1 Airless Bottle Molding

Injection molding: For plastic vacuum bottles, injection molding is a common process. The plastic raw material is heated and softened, then injected into the mold cavity, and cooled to form the bottle body, pump head and other parts. This process is suitable for producing parts with complex shapes and precise dimensions.

Blow molding: Another method of making plastic vacuum bottles is blow molding. The plastic raw material is first heated and softened to form a parison, and then air is blown into the parison to make it expand and fit the shape of the mold cavity. This process is often used to produce bottles with large capacity and thin walls.

Glass blowing: For glass vacuum bottles, the glass material is heated to a molten state and then blown into the desired shape in the mold by air pressure.

2.2 Airless Bottle Surface Treatment

Coating: To improve the appearance and feel of the bottle, surface coating processes such as UV coating and matte coating can be used. UV coating can make the bottle surface shiny and scratch-resistant, while matte coating makes it more textured and high-end.

Printing: Brand logo, product information and decorative patterns are usually printed on the bottle by screen printing, hot stamping and other printing methods. Screen printing is suitable for printing simple patterns and texts, and hot stamping can produce a shiny metal effect, which is very suitable for highlighting the brand logo.

Assembly: After the bottle body and pump head are formed and surface treated, they are assembled together. The pump head is installed on the bottle body, and some vacuum bottles may also need to be installed with accessories such as inner plugs and outer covers to ensure the sealing and usability of the product.

2.3 Airless Bottle Quality Inspection

Appearance inspection: Check whether there are scratches, bubbles, color differences and other defects on the surface of the bottle body. The printing should be clear and complete without stains, fading, etc.

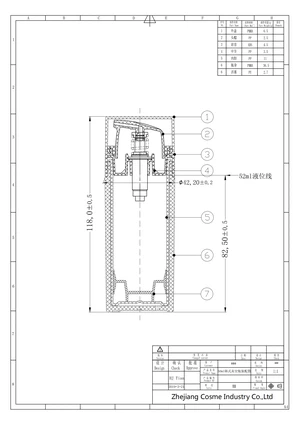

Dimension inspection: Measure the dimensions of the bottle body, pump head and other components to ensure that they meet the design requirements. The bottle body diameter, height, wall thickness and pump head size should all be within the specified tolerance range.

Sealing performance test: Test the sealing performance of the vacuum bottle to ensure that there is no leakage. This can be done by injecting water or air into the bottle and observing whether there is leakage for a certain period of time.

Functional test: Test the pumping function of the pump head to ensure that it can smoothly pump out the liquid and the amount of liquid pumped out each time is within the specified range.

2.4 Airless Bottle Packaging and Delivery

Packaging: Vacuum bottles that have passed the inspection are usually packed in cartons or other packaging materials to protect them during transportation and storage. Inner packaging such as foam or plastic partitions can be used to prevent the bottles from colliding and scratching each other.

Delivery: According to customer requirements, we will arrange transportation to deliver the customized vacuum bottles to the customer's designated location. The mode of transportation can be selected according to the quantity of goods and delivery time requirements, including sea transportation, air transportation and land transportation.

Professional Airlrss Bottle Manufacturer Solutions

1. Is the material safe and non-toxic and meets the cosmetic packaging standards? How tight is the bottle and pump head? Is there any risk of leakage?

Qualification certification: We have ISO quality system certification, cosmetic packaging material safety certification, etc., which meet industry standards.

Display material information: We will introduce the materials used in vacuum bottles in detail, such as food-grade plastics, medical-grade glass, etc., explain their safe and non-toxic characteristics, and provide detailed parameters and source certificates of the materials.

Conduct sealing test demonstration: We conduct sealing tests on vacuum bottles through videos or on-site demonstrations, such as pressure tests, inversion tests, etc., to show buyers the good sealing of the bottle body and pump head to ensure no leakage.

Provide cases and word-of-mouth proof: Share cooperation cases with other well-known cosmetics brands, provide customer evaluations and feedback, and prove the reliability and stability of our products.

Quality commitment: Provide quality assurance terms and promise that if there are product quality problems caused by material or sealing problems during use, we will be responsible for return or compensation for losses.

2. Guarantee to customers that as a vacuum bottle manufacturer, I can meet the customer's order volume requirements? Delivery cycle?

Production scale: We have 5 automated production lines, each with a daily output of 10,000 vacuum bottles.

Human resources: 200 permanent employees, who can flexibly arrange overtime or recruit temporary workers according to the order volume.

Cooperation cases: Cases of large-scale orders undertaken, such as the one-time supply of 500,000 vacuum bottles for a well-known brand, we are capable of undertaking large orders.

Guarantee delivery cycle

Provide production scheduling: After signing a contract with the customer, a detailed production scheduling will be provided to clarify the time nodes of each production stage.

Establish a communication mechanism: Arrange a dedicated person to connect with the customer, communicate the production progress regularly, and provide timely feedback and solutions if there are any problems.

Commitment to breach of contract liability: It is clear in the contract that if the delivery is delayed due to its own reasons, it is willing to bear the corresponding breach of contract liability.

3. Are there multiple specifications and styles to choose from? Can it be customized according to requirements?

Specifications and styles

Capacity specifications: There are many common capacities such as 15ml, 20ml, 30ml, 40ml, 50ml, 80ml, 100ml, 120ml, 150ml, etc.

Material: Mainly includes plastics such as AS, PP, PETG, etc., and glass materials.

Appearance design: There are elliptical and cylindrical shapes in terms of shape, and the surface treatment processes include spray color, silk screen, hot silver, frosting, etc. The appearance style covers simple fashion, cute cartoon, etc.

Pump head type: There are different pump head designs such as push type and spray type.

Customized service

Customizable content: The bottle shape, color, material, processing technology, etc. can be tailored according to customer needs, and products can be developed and produced according to the provided drawings or samples.

4. How to solve quality problems? Do you provide return and exchange services for damaged packaging?

Measures to solve quality problems

Quick response: After receiving customer feedback on quality problems, we will respond within 24 hours and arrange professionals to communicate with customers to understand the problem in detail.

Investigation and analysis: Immediately investigate and analyze the problem products to determine the cause of the problem. If it is a problem in the production link, we will trace the production process, find out the root cause and take improvement measures.

Solution: According to the severity and specific circumstances of the problem, provide customers with solutions such as replacement, replenishment or refund to ensure that the customer's losses are minimized.

Return and exchange service

Damaged packaging processing: For damaged packaging during transportation, we provide unconditional return and exchange services. Customers will provide feedback within 3 working days after receiving the goods. We will arrange for reissue or replacement in time after confirming the situation.

Return and exchange process: After the customer submits a return or exchange application, we will provide a detailed return address and process guidance. After receiving the returned goods and confirming that they are correct, we will quickly handle the exchange or refund to ensure that the customer can receive qualified products in a timely manner.

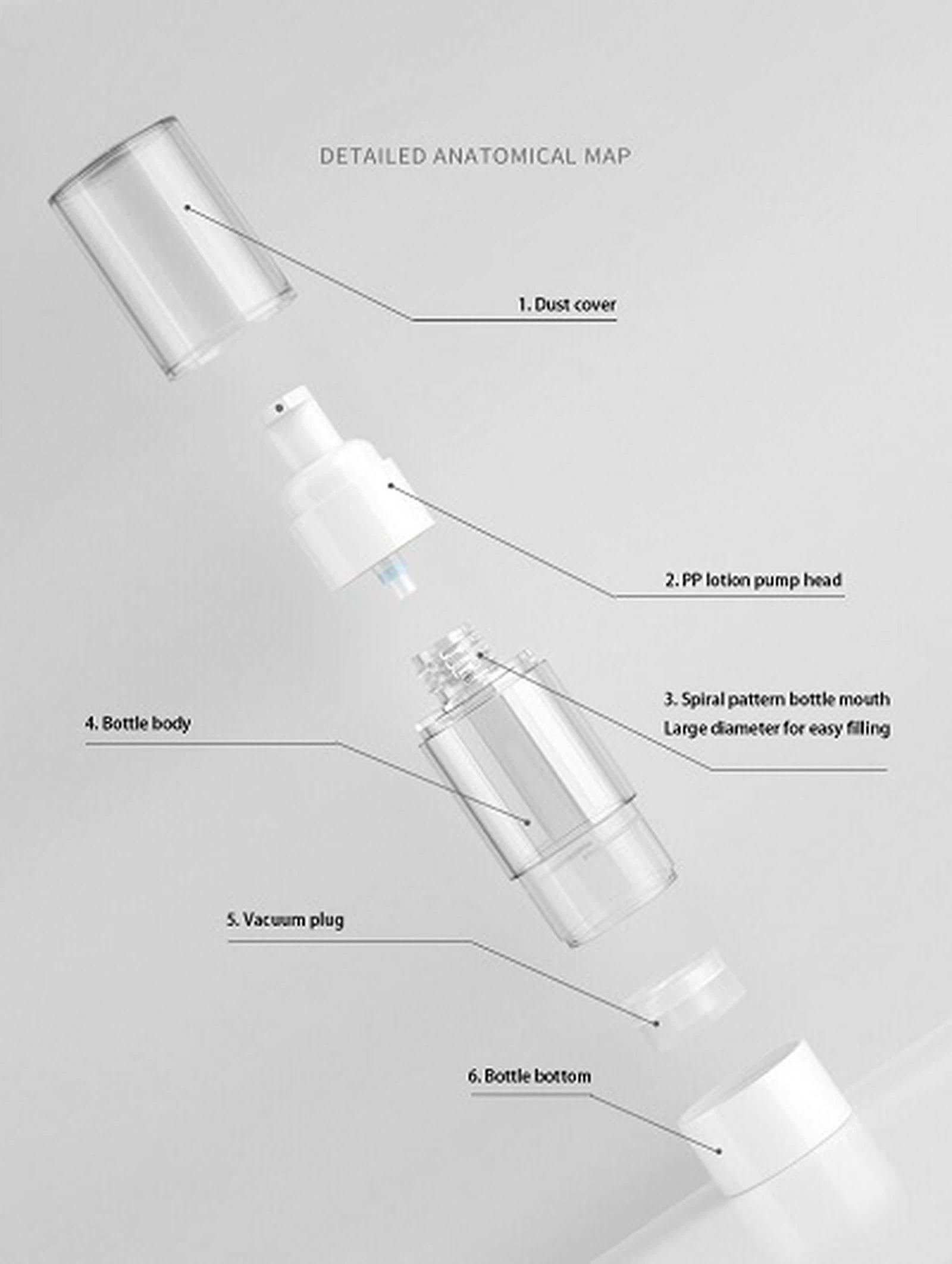

What is a cosmetic Airless Bottles

A cosmetic vacuum bottle is usually composed of a bottle body, a bottle cap, a press pump head, a vacuum piston and other parts. The bottle body is used to hold cosmetics, the bottle cap plays a sealing and protective role, the press pump head is used to control the use of the product, and the vacuum piston is the key component to achieve the vacuum function.

Working principle of Airless Bottles

The vacuum bottle uses the principle of atmospheric pressure and vacuum negative pressure. When the pump head is pressed, the air in the bottle is discharged, and a negative pressure environment is formed in the bottle. Under the action of the external atmospheric pressure, the cosmetics in the bottle are pressed against the pump head and squeezed out for use. When the pump head is released, the vacuum piston will automatically rise according to the amount of cosmetics remaining in the bottle, always maintaining the vacuum state in the bottle to prevent air from entering.

How to Open a Vacuum Pump Bottle

Different vacuum pump bottles have slightly different ways of opening. The common steps are: first check whether the bottle cap has a safety buckle or lock, if so, open it first; then hold the bottle body and rotate the bottle cap counterclockwise. If it is tight, you can use appropriate force or use a towel to increase friction; some have a pressing pump head, so you need to pull the pump head upward or rotate it open, and then press the pump head to absorb the contents. If the vacuum pump bottle is made of brittle materials such as glass, pay attention to the force when operating to avoid damage.

How to Refill a Vacuum Pump Bottle

The steps to refill a vacuum pump bottle are as follows: first, separate the pump head from the bottle body, clean the bottle body and pump head to ensure that there are no residual impurities. Then slowly pour the cosmetics to be filled into the bottle, being careful not to overfill it. Then, align the pump head with the bottle mouth and press it down vertically to ensure that it is firmly installed and sealed. Finally, gently press the pump head to expel the internal air so that the pump head can absorb the cosmetics normally. If there is overflow during the filling process, wipe it clean in time to avoid affecting the use and appearance of the bottle.

Can I reuse my vacuum pump bottle?

Vacuum pump bottles can usually be reused, but there are certain conditions. If the bottle body and pump head are not damaged, the sealing performance is good, and they are thoroughly cleaned and disinfected to remove residual cosmetics and bacteria, they can be reused. However, some bottles made of poor materials, aged or deformed after long-term use, may not guarantee good performance. In addition, different cosmetics have different ingredients. If you want to switch to different products, you need to ensure compatibility, otherwise reactions may occur and affect product quality. It is recommended to try them on a small scale first.

How Vacuum Pump Bottles Work

The working principle of the vacuum pump bottle is based on atmospheric pressure and vacuum negative pressure. When the pump head is pressed, the air is discharged, and negative pressure is formed in the bottle. The atmospheric pressure outside the bottle presses the liquid in the bottle toward the pump head to squeeze it out. After releasing the pump head, the vacuum piston automatically rises due to the pressure change in the bottle, filling the space vacated by the liquid, maintaining the vacuum state in the bottle, preventing air from entering, ensuring that the liquid in the bottle is stored in an airless environment, and each time the pump head is pressed, the liquid can be quantitatively squeezed out under pressure, achieving convenient and hygienic use.

How to Clean a Vacuum Pump Bottle

To clean the vacuum pump bottle, follow these steps: first unscrew or pull out the pump head from the bottle, pour out the remaining liquid, rinse the inside of the bottle with warm water, and use a soft brush to clean stubborn stains. If the pump head is detachable, try to disassemble it, wipe it with a soft cloth dipped in warm water or mild detergent, and be careful to avoid water entering the spring and other parts. Then rinse the bottle and pump head thoroughly with clean water, let them dry naturally or use a clean towel to absorb the moisture. Before assembly, check whether each part is dry and make sure there is no residual moisture before reassembling.

What is a vacuum pump bottle

A vacuum pump bottle is a packaging container used to store and take liquid products. It uses a special pump head and bottle body design to expel air by pressing the pump head to form a vacuum negative pressure, so that the liquid in the bottle is squeezed out under the action of the external atmospheric pressure. It has the characteristics of quantitative taking, preventing liquid backflow and air from entering, and can effectively maintain the freshness and stability of the liquid in the bottle. It is widely used in cosmetics, skin care products, medicines and other fields, providing users with a convenient and hygienic use experience.

Custom Airless bottles that can control the output of each pump

If you want to customize a vacuum bottle that can control the output of each pump, you can start from these aspects. As a professional cosmetic bottle manufacturer, communicate with us to clarify the output value range, such as expecting 0.2-0.5 ml to be pumped out each time. Then we use precise metering devices in the design of the pump head, such as a combination of a piston with a specific specification and a flow restriction hole, to ensure that each time the pump head is pressed, the set amount of content can be accurately output to meet the needs of strict control of the dosage.

Are vacuum pump bottles leak-proof?

COSME vacuum pump bottles usually have good leak-proof performance. The pump head and the bottle body are generally tightly sealed, such as using sealing rings and other components to prevent liquid from leaking from the interface. Moreover, during normal use and storage, the vacuum environment inside the bottle also helps reduce the risk of liquid leakage due to pressure changes and other reasons.

How to Use a Airless Spray Bottle

First clean the spray bottle and dry it to ensure that there are no residual impurities inside.

Pour the liquid to be sprayed into the bottle through the bottle mouth, and be careful not to exceed the maximum capacity line.

Tighten the bottle cap to ensure a good seal.

Hold the bottle body, aim the spray head in the direction you need to spray, press the spray head, and use the vacuum principle in the bottle to spray the liquid in the form of mist.

After use, place the spray bottle in a cool and dry place, avoiding direct sunlight and high temperature environment.

What are Airless bottles used for?

Vacuum bottles have a wide range of uses, mainly including: in the cosmetics field, they are used to store lotions, creams, essences, etc., which can be used accurately and keep the products fresh; in the medical field, they can hold medicines, disinfectants, etc. to prevent pollution and deterioration; in the food industry, they can be used to hold sauces, seasonings, etc. to extend the shelf life; in industry, they are used to store chemical liquids such as lubricants and inks to avoid reactions with air, and can also achieve quantitative supply and improve production efficiency.

What are the uses of vacuum pump bottles?

Cosmetics industry: It can prevent skin care products such as essences and lotions from oxidizing and deteriorating, and it is convenient and hygienic to press and take, ensuring the stability of the active ingredients of the product.

Medical field: It is used to store eye drops, topical smears, etc., accurately control the dosage, avoid bacterial contamination, and ensure the safety and effectiveness of drugs.

Food field: It can be used to hold seasoning sauces, honey, etc., reduce air contact, delay deterioration, and maintain food flavor and quality.

Other aspects: In industry, it is used to store precision instrument cleaning agents, etc. to prevent volatilization and reaction; in the home, it can be used to hold softeners, etc., which are convenient for quantitative use.

What is a cosmetic Airless bottle?

A Airless bottle is a container used to package cosmetics. It uses the principle of vacuum negative pressure and is usually composed of a bottle body, a vacuum pump head, a piston and other parts. The piston in the bottle will rise as the contents are used, so that the bottle always maintains a vacuum state, which can effectively prevent cosmetics from contacting with air, avoiding oxidation and deterioration, and extending the shelf life of the product. At the same time, it can also accurately control the dosage, maintain the active ingredients of cosmetics, and provide users with a more hygienic and convenient use experience. It is commonly used in the packaging of essences, lotions, creams and other cosmetics.

As one of the most professional airless bottles manufacturers and suppliers in China, we're featured by quality products and good service. Please rest assured to wholesale high-grade airless bottles from our factory.

airless baby bottles, airless bottles baby, gold airless bottle